Haas Vf1 Operator Manual

Tech just serviced this 05 vf1 with reinshaw toolsetter and probe. However for some reason he ran out of time/couldn't get the probe to work.

I tried the calibrate probe xy macro that came with the machine and the probe does not work however when i manually move the stylus the controll will beep so i assume that it is getting trigger info. Tried the toolsetter and the macro for that seems to do all but what its supposed to do. I get a probe open alarm when i try the probe calibrate xy.

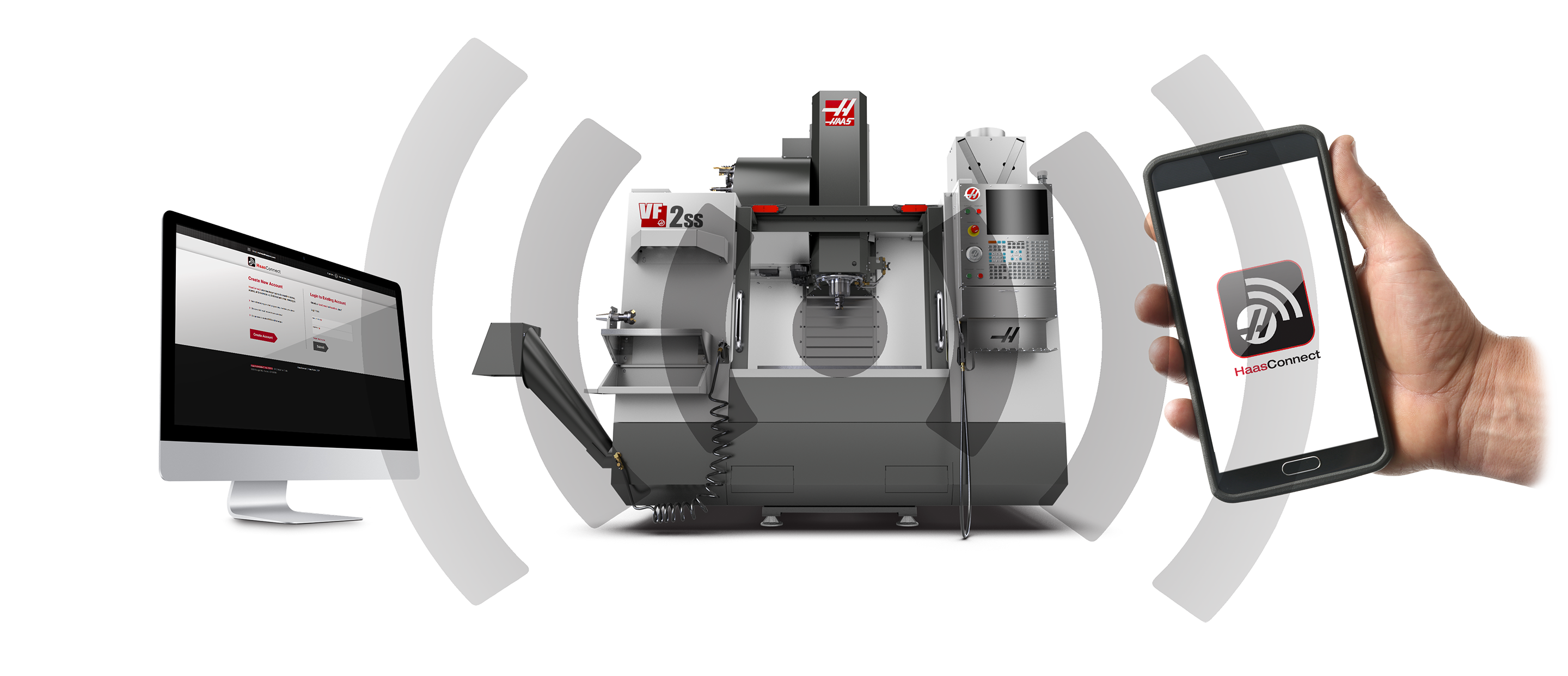

This Used 2008 Haas VF-1 CNC Vertical Mill is for sale at ReSell CNC (407) 478-8181. It is equipped with the SMW200S Manual Pallet. Contact Haas Haas Europe. G-Codes / M-Codes Operator's Manuals Installation Requirements. Instructional Videos. Haas How-To Video Collection: Operator Tips.

Are you specifying a diameter? On my Fanuc based machines, you need to call G65P9802DX.XX where X.XX is the nominal diameter of your bored hole. If you are getting a beep on manual activation I think you are good to go, at least up to the renishaw interface.

There may still be problems between it and the Haas control though. Try manually calling a G31 move with the probe safely away from anything at a slow feed rate, and manually trip the probe tip. It should immediately stop if everything is hooked up correctly. Do you have the manual for the inspection plus software?

I think I have a pdf copy if you need it. I looked back though the macros on my control, and it looks like the error is probably happening in macro O9726, which is the basic measurement function that is called by a lot of the higher level macros. Your O9802 is calling O9721 for an X axis diameter measurement, which in turn is calling O9726 for each of the X axis measurement moves. When it gets to about line 38 of O9726, it calls a G31 move to what it thinks is the target position of your bore. For some reason it is tripping the probe input immediately, and in the following lines seeing that the probe hasn't moved the required minimum distance, and returning a probe open error.

The only thing I can think of at this point is to make sure that your probe batteries are fresh, and maybe look into how your probe is turned on. On my M12 probe, you need to issue a special M code to turn the probe on before each use. If not, it will give the same error you are getting. Some probes required spinning on/off.

Hope this helps. I looked at those programs and it looks like they got imported for some reason with a bunch of (parenthases) in the program. That looks like the error.

Need to reload the programs but talked to haas for a split second and they said they have seen this before and if i try to import them again it will happen unless i change a parameter but they didn't tell me which one. Said they would call me right back, but like most techs. No call thanx for the help.

These macro things are fun but pretty complicated. You have different errors now but the reason why I asked about 'line of sight' is because most people have the habit of checking the skip signal where the probe is within an easier reach. This may not be the same case as where the probe is during calibration or part cycle. As for differences in program loading.

Try reloading programs again. Only this time, slow the baud rate way down.

You may be shoving data too fast and the control is making mistakes (that is if you're using the serial I/O and not USB or Floppy). I'm using USB to import.

VF-1 - € 40,995.00 TRAVELS S.A.E. METRIC X Axis 20 ' 508 mm Y Axis 16 ' 406 mm Z Axis 20 ' 508 mm Spindle Nose to Table ( max) 24 ' 610 mm Spindle Nose to Table ( min) 4 ' 102 mm TABLE S.A.E.

METRIC Length 26 ' 660 mm Width 14 ' 356 mm T-Slot Width 5/8 ' 16 mm T-Slot Center Distance 4.92 ' 125.0 mm Number of Std T-Slots 3 3 Max Weight on Table (evenly distributed) 3000 lb 1361 kg SPINDLE S.A.E. METRIC Max Rating 30 hp 22.4 kW Max Speed 8100 rpm 8100 rpm Max Torque 90 ft-lb @ 2000 rpm 122 Nm @ 2000 rpm Drive System Inline Direct-Drive Inline Direct-Drive Max Torque w/opt Gearbox 250 ft-lb @450 rpm 339 Nm @ 450 rpm Taper CT or BT 40 CT or BT 40 Bearing Lubrication Air/Oil Injection Air/Oil Injection Cooling Liquid Cooled Liquid Cooled FEEDRATES S.A.E.

METRIC Rapids on X 1000 in/min 25.4 m/min Rapids on Y 1000 in/min 25.4 m/min Rapids on Z 1000 in/min 25.4 m/min Max Cutting 650 in/min 16.5 m/min AXIS MOTORS S.A.E. METRIC Max Thrust X 2550 lb 11343 N Max Thrust Y 2550 lb 11343 N Max Thrust Z 4200 lb 18683 N TOOL CHANGER S.A.E. METRIC Type Carousel (SMTC Optional) Carousel (SMTC Optional) Capacity 20 20 Max Tool Diameter (full) 3.5 ' 89 mm Max Tool Weight 12 lb 5.4 kg GENERAL S.A.E.

Haas Vf1 Operator Manual

METRIC Air Required 4 scfm, 100 psi 113 L/min, 6.9 bar Coolant Capacity 55 gal 208 L.