Aiag Mfmea Manual

Failure Mode and Effects Analysis (FMEA) is an analytical method used to ensure potential problems are considered and addressed throughout the product and process development process. Failure Modes are the ways in which something might fail.

The failures are actual or potential errors or defects, especially those affecting the customer. Effects Analysis refers to studying the consequences or effects of those failures.

Aiag Fmea Manual 4th Edition

The Difference between MFMEA and PFMEA. 30230 Orchard Lake Rd. The AIAG Reference. Manual states on page 49: “These controls can be process.

The objective of the Pence Martial Arts Law Enforcement. To instructor directions. These manuals do. Of instructors, contact Crawford’s MMA. Browse and Read Instructor Manual Mma Instructor Manual Mma How a simple idea by reading can improve you to be a successful person? Reading is a very simple activity. Navedtra 134 navy instructor manual.

Using FMEA, failures are prioritized by the:. Seriousness of their consequences. Frequency of their occurrence.

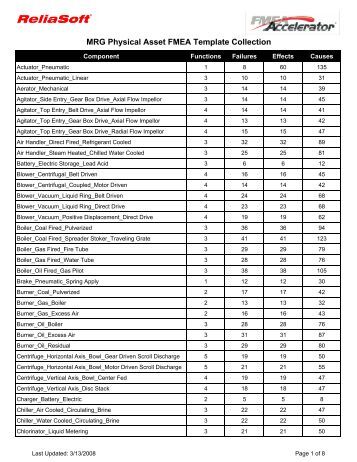

Likelihood of their detection The purpose of FMEA is to take actions to eliminate or reduce failures, starting with the higher priority ones. Design FMEA The Design FMEA, referred to as DFMEA, supports the design process at the system, subsystem, interface, and component level to reduce the risk of product failures. Process FMEA The Process FMEA, referred to as PFMEA, supports the development of manufacturing and assembly operations by reducing the risk of process failures. FMEA Reference Manual The FMEA 4th Edition is a reference manual to be used by suppliers to Chrysler, Ford, and General Motors as a guide to assist them in the development of both Design and Process FMEAs. The manual can be ordered from AIAG. A one page FMEA 4th Edition Errata Sheet has been issued and can downloaded at this. MFMEA A special Machinery FMEA (MFMEA) reference manual is available for tooling and equipment suppliers.

The MFMEA 2nd Edition can be ordered.